Inspection

Quality and Inspection

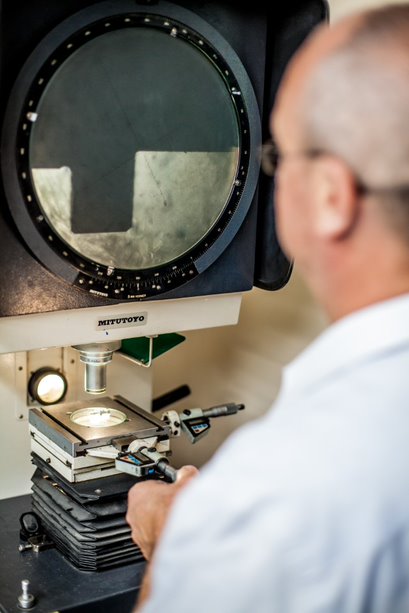

Accuracy and quality drive everything we do and our dedicated inspection facilities includes the latest vision inspection technology with the Keyence IM-8000 and 3 axis CMM using the Mitutoyo Euro-M 544, with accuracy within +/- 0.0015mm.

We also have AS9100 and ISO 9001 Quality Approval as well as Fit For Nuclear (F4N) accreditation and Cyber Essentials Plus.

In 2025 we invested in the very latest vision inspection technology with the Keyence IM-8000 automated visual inspection system – the latest addition to our already impressive suite of precision measuring equipment.

With a measuring accuracy of up to 0.5 microns, the IM-8000 brings exceptional speed, repeatability, and confidence to our inspection process. This technology further strengthens our ability to support customers requiring the highest levels of precision and quality.

Alongside our accreditations – AS9100, ISO9001, Cyber Essentials Plus, and Fit For Nuclear – the Keyence IM-8000 reinforces our position as a trusted partner for demanding, high-integrity sectors.

At WES, we’re committed to combining advanced technology, proven expertise, and rigorous standards to deliver components our customers can rely on.

Our Capabilities

Unique parts for the most demanding situations, from prototypes to full production runs. Our highly experienced designers will support your machining project from start to finish.

Machines

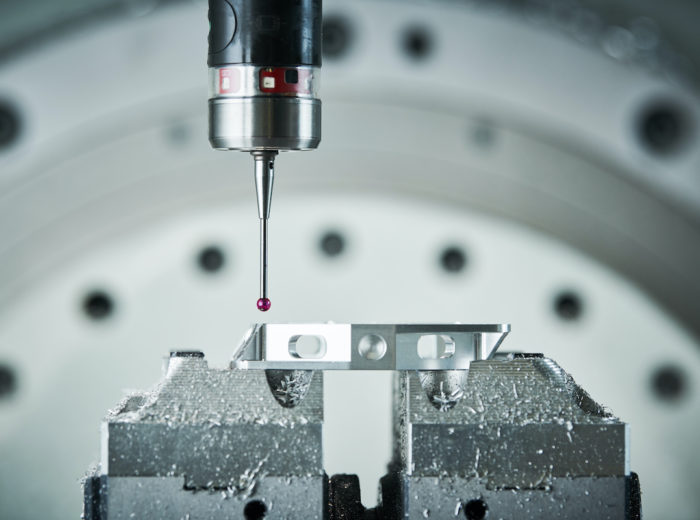

Industry wide we are recognised for our precision CNC machining, advanced infrastructure and engineering excellence

Find out moreMaterials

From Tungsten Carbide to Inconel to Aluminium and everything in between, we work with a wide range of metals

Find out more